Your professional one-stop solution provider for automatic feeding system.

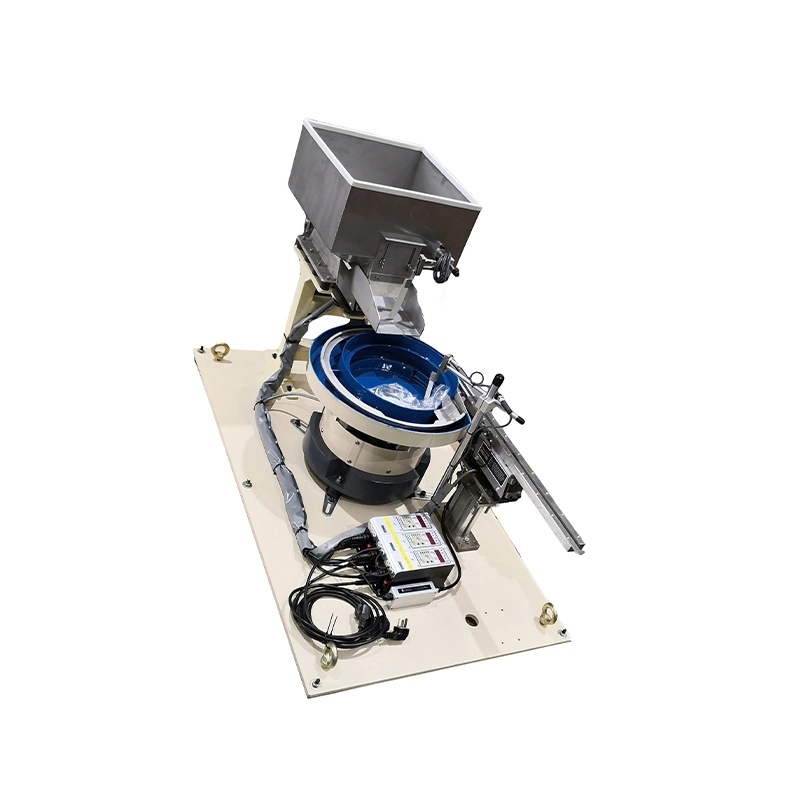

Plastic clip vibratory bowl feeder for automotive TUV-S01

Detail description

Linear track sensor

If the linear track is full of clips, this sensor will indicates in red light to stop the bowl feeder. In contrast, if the track is lack of clips, this sensor will indicates in green light, and the bowl feeder will keep feeding clips into the linear track.

Bowl condition monitoring sensor

This sensor can indicate the clips level in the bowl. If the bowl is full of clips, this sensor will indicates in red light to stop the bulk hopper. In contrast, if the bowl is lack of clips, this sensor will indicates in green light, and the bulk hopper will keep feeding clips into the bowl. It can observably reduce the fault caused by too many clips in the bowl.

Surface coating of the bowl

This PU coating of the bowl surface can reduce abrasion of the clips, also the noise level of the bowl feeder.

Hopper sensor

This sensor can send out a signal to indicate lacking of clips in the hopper. Thus operator could add more clips into the hopper in time.

Lifting bolts

In consideration of big weight of this machine, we have installed four lifting bolt on the corners of the board, so customer can using forklift or crown block to load and unload it.

size

FAQ

Contact: Mr. Monte Liu

Tel: 86-13652039993E-mail: monte_liu@taiuni.com

Add: Building 35#, No. 4 Gaotai Road, Binhai High-Tech New Area, Tianjin, China