Your professional one-stop solution provider for automatic feeding system.

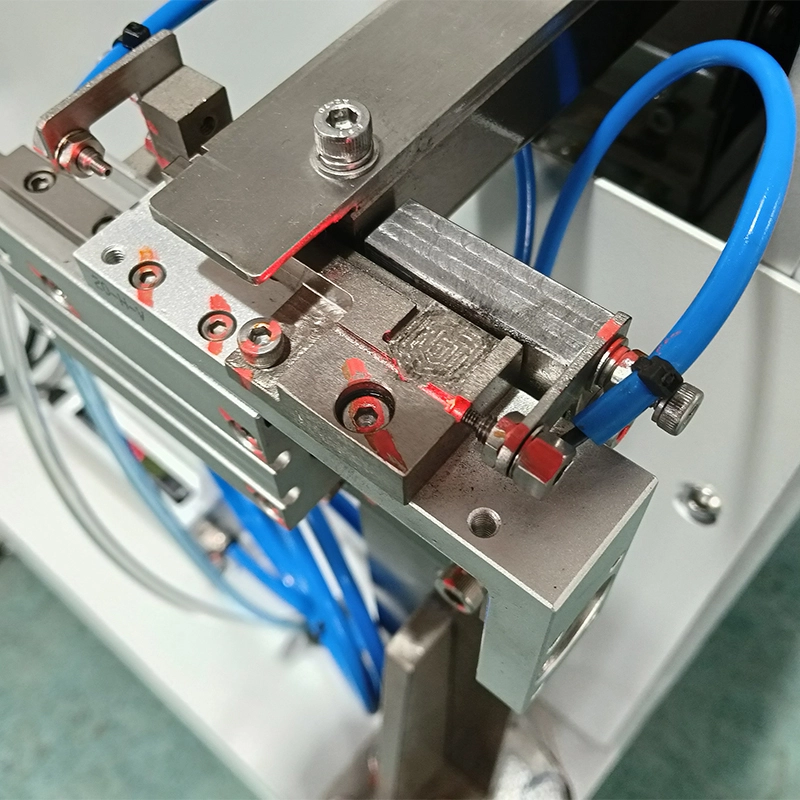

Nest part escapement side shuttle mechanism for hexgon nut working with vibratory bowl feeder

Detail description

Most commonly used parts escapement mechanisms

This parts escapement mechanism consists of a pneumatic cylinder, a set of specially designed machined nest fixture, a pair of through-beam fiber optic sensors, and a support frame. It is typically used in conjunction with a linear feeder or conveyor belt, separating parts delivered in a continuous stream one at a time and delivering it to a designated position for downstream processes to pick up. The mechanism features a simple structure, high stability, compact footprint, and low noise, making it one of the most commonly used parts escapement mechanisms in automated feeding equipment. For different parts, only the custom-designed machined chutes need to be replaced, ensuring excellent versatility.

The general sequence of the operation

● Starting position / home position: At the beginning of the cycle, the nest fixture is meeting with the linear chute.

● Move forward: When one hexgon nut is feed into the nest fixture and be detected, the pneumatic cylinder drives the nest fixture move forward to a fixed position. The nest fixture is specially designed and machined according to the shape of the hexgon nut. During the separation process, it can and will only separate one hexgon nut at a time without causing damage to other hexgon nuts in the linear track.

● Move backward: After the hexgon nut in the nest fixture being picked up and placed in another position, the nest fixture is drive by the pneumatic cylinder backward to the home position, and then the next cycle is started.

Fiber optic amplifier

The fiber optic amplifier can indicate and adjust detection parameters, and accurately determine whether there is material in the nest fixture.

Bracket

This nest parts escapement is set on a bracket to ensure the stability of its structure. This bracket is also machine tooled.

size

FAQ

Contact: Mr. Monte Liu

Tel: 86-13652039993E-mail: monte_liu@taiuni.com

Add: Building 35#, No. 4 Gaotai Road, Binhai High-Tech New Area, Tianjin, China