Your professional one-stop solution provider for automatic feeding system.

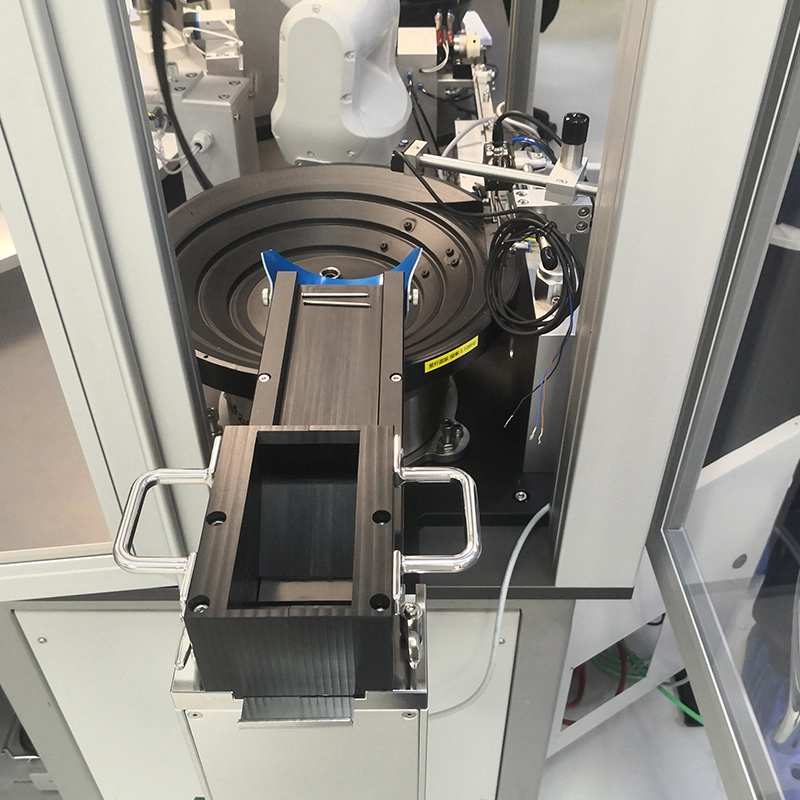

CNC Machining Vibratory feeder for screw rods in medical field customized feeding system

Detail description

Linear track sensor

If the linear track is full of thread rods, this sensor will indicates in red light to stop the bowl feeder. In contrast, if the track is lack of tread rods, this sensor will indicates in green light, and the bowl feeder will keep feeding tread rods into the linear track.

Bowl condition monitoring sensor

This sensor can indicate the tread rods level in the bowl. If the bowl is full of tread rods, this sensor will indicates in red light to stop the bulk hopper. In contrast, if the bowl is lack of tread rods, this sensor will indicates in green light, and the bulk hopper will keep feeding tread rods into the bowl. It can observably reduce the fault caused by too many tread rods in the bowl.

Bowl sorting sensor

This sensor can indicate the disorientated thread rods, thus the compressed air flow can blow them off back into the bowl.

Material of the bowl top

Considering the fragile surface of the thread rods, we adopted nylon for the bowl top to minimize production damage. Also it can reduce the noise of the machine while it working.

Hopper

The hoppers can greatly extend the storage volume of work-pieces. They have different advantages. You can select the right model according to your individual requirements.

Parts escapement mechanism

The design of parts escapement mechanism can separate one single screw rod to the fixed position, where robot can pick it precisely.

size

FAQ

Contact: Mr. Monte Liu

Tel: 86-13652039993E-mail: monte_liu@taiuni.com

Add: Building 35#, No. 4 Gaotai Road, Binhai High-Tech New Area, Tianjin, China